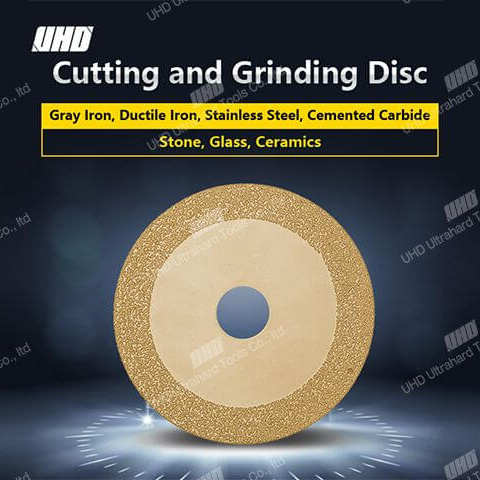

In today's advanced manufacturing landscape, where precision and durability are paramount, brazed diamond grinding wheels have emerged as the gold standard for high-performance abrasive tools. Combining superior wear resistance with exceptional safety features, these grinding wheels have profoundly impacted various industrial sectors, notably in the machining of ultra-hard materials.

The demand for abrasives capable of handling complex, high-precision tasks continues to grow with the advancement of aerospace, automotive, semiconductor, and tooling industries. Hard and brittle materials—such as silicon carbides, tungsten carbides, ceramics, and hardened steels—require grinding solutions that not only deliver impeccable surface finish and dimensional accuracy but also extend tool life to reduce downtime. Brazed diamond grinding wheels, known for their robust mechanical bonding through high-temperature brazing, present a remarkable solution addressing these needs.

Youde Superhard Tools Co., Ltd. has pioneered advanced brazing techniques that significantly enhance the longevity and safety of diamond grinding wheels. Their proprietary high-temperature brazing processes ensure an ultra-strong bond between diamond grains and the steel wheel core, achieving outstanding wear resistance that generally surpasses traditional resin or metal bond wheels by 40–60% in lifespan under comparable conditions. Furthermore, these wheels maintain their sharpness and grinding efficacy even during extended use, reducing frequency of wheel replacement and associated labor costs.

Stringent quality controls and durable raw materials contribute to the wheels’ operational safety — highly relevant in automated manufacturing lines where minimizing the risk of wheel fragmentation is critical. Youde’s consistent product performance has earned certifications from global industrial standards organizations, reinforcing trust among international buyers.

| Metric | Brazed Diamond Wheels | Traditional Metal Bond Wheels |

|---|---|---|

| Wear Resistance | Up to 60% higher | Standard |

| Grinding Accuracy | < 5 microns tolerance | ~10 microns tolerance |

| Operational Safety | Certified ISO 2768, fracture resistant | Basic conformity |

| Tool Life | 30-50% longer use cycle | Baseline |

The industrial manufacturing ecosystem is evolving to emphasize lean production, environmental sustainability, and integrated automation. Brazed diamond grinding wheels fit seamlessly into this modern narrative by decreasing abrasive waste and energy consumption due to their extended lifespan and consistent performance. Industry analyses forecast a growth CAGR of approximately 5.8% over the next five years for diamond abrasive tools, largely driven by rising demand in electronics and automotive sectors, where ultra-precise machining is non-negotiable.

To showcase these breakthroughs, Youde has launched its Global Process Innovation Tour, a comprehensive campaign combining online webinars, technical demos, and hands-on exhibitions to connect with industry professionals worldwide. This initiative places a spotlight on the real-world benefits of brazed diamond grinding wheels—highlighting case studies that demonstrate up to 25% improvement in grinding efficiency and a 15% reduction in operational downtime at key client sites.

Targeted at manufacturing engineers, procurement managers, and R&D specialists, the tour emphasizes user engagement through interactive Q&A sessions and expert panel discussions. This multi-channel approach maximizes outreach and leverages data-driven insights to tailor messaging, strengthening Youde's brand authority and driving qualified inquiries.

One prominent case involved a semiconductor wafer manufacturer who reported a 35% reduction in abrasive consumption after switching to Youde’s brazed wheels, correlating directly with lowered production costs without compromising finishing quality. Another automotive tooling enterprise experienced a 20% decrease in wheel-related downtime, thanks to the wheels’ fracture-resistant brazed bonds enhancing workplace safety.

These empirical results, backed by quantitative data and positive user feedback, have been instrumental in fostering trust among existing and prospective clients, bolstering loyalty and expanding market share.

Youde’s strategic integration of digital platforms and physical events ensures broad visibility. SEO-optimized content highlighting keywords such as brazed diamond grinding wheels, abrasive wear resistance, and industrial manufacturing innovation fuels organic discovery on search engines. Simultaneously, targeted Google Ads and LinkedIn campaigns sharply focus on industrial procurement audiences across North America, Europe, and Asia.

This synergetic marketing enables a virtuous cycle of lead generation, brand familiarity, and customer education—essentially translating innovation into commercial success.