In modern industrial manufacturing, the demand for high-precision machining tools with exceptional wear resistance has never been greater. Among these, brazed diamond grinding wheels stand out as a paragon of innovation and performance. Leveraging cutting-edge brazing technology combined with ultra-hard diamond particles, these grinding wheels redefine standards for efficient material removal and prolonged service life in demanding applications.

The brazing process, central to these diamond grinding wheels, involves the metallurgical bonding of superabrasive diamonds to a metal backing, yielding superior structural integrity and enhanced heat dissipation. This synergy increases grinding efficiency by up to 30% compared to traditional electroplated wheels, while drastically reducing thermal damage to the workpiece.

The incorporation of ultra-hard diamond grit—with Mohs hardness of 10 and exceptional toughness—enables the grinding wheels to maintain sharp cutting edges under high rotational speeds, ensuring consistent surface finishes and superior dimensional accuracy. Research and industrial testing demonstrate these wheels can endure continuous use exceeding 60 hours in high-stress environments, reflecting a 40% improvement in lifespan.

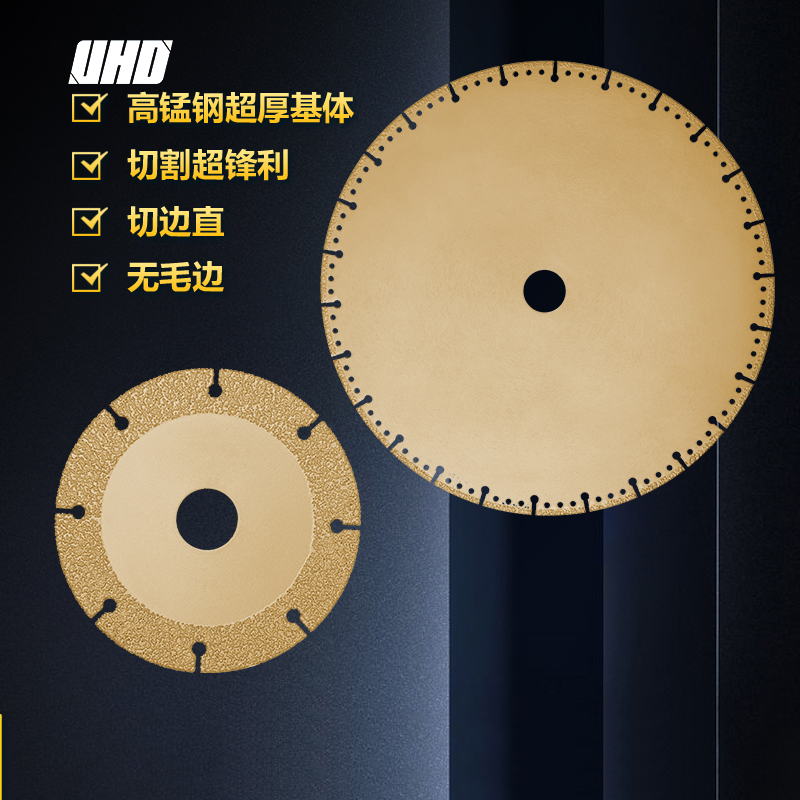

Recognizing the diverse requirements of global manufacturing sectors, these brazed diamond wheels are offered in an extensive range of sizes and shapes—from shallow bowl shapes for delicate surface refinement to deep cup geometries suited for aggressive stock removal. This versatility directly addresses the needs of aerospace, automotive, and precision tooling industries, where customization correlates with productivity gains.

| Wheel Type | Typical Diameter (mm) | Applications | Average Service Life (hours) |

|---|---|---|---|

| Bowl-Shaped Brazed Diamond Wheels | 100-150 | Fine grinding of carbide and ceramics | 60+ |

| Cup-Shaped Brazed Diamond Wheels | 150-200 | High stock removal in tool and die making | 70+ |

| Custom-Contour Brazed Wheels | Varied | Precision profile grinding in aerospace parts | 65+ |

The relentless advancement of industries such as electronics, automotive, and aerospace spurs an increasing reliance on high-precision, durable tooling solutions. The industry's shift toward lightweight materials like ceramics and composites demands grinding solutions that combine exceptional hardness with thermal stability—qualities intrinsic to brazed diamond technology.

Manufacturers prioritizing operational safety and sustainable production are drawn to these grinding wheels for their predictable wear behavior and reduced downtime. Cutting-edge coatings and metallurgical improvements not only improve wear resistance by 25% but also contribute to safer operator environments by minimizing dust generation.

The “Enduring Wear, Precision Forged” global innovation tour exemplifies the brand’s dedication to advancing grinding technologies and fostering customer trust. Through comprehensive demonstrations and technical exchanges across key manufacturing hubs, the tour reinforces the brand’s ethos of uncompromising quality and exacting standards.

Feedback from industry leaders highlights significant improvements in cycle times and surface finish quality when integrating these grinding wheels. This, coupled with meticulous safety protocols and longevity assurances, bolsters confidence in both the product and the brand.

Safety remains paramount in operating abrasive tools. Brazed diamond wheels are engineered to meet rigorous international safety standards (ISO 603:2020), employing balanced designs and robust bonding methods to minimize vibration and structural failure risk. Their enhanced life cycle reduces the frequency of change-outs, translating to fewer operational interruptions and improved workplace ergonomics.

Empirical data from industrial case studies reveal a mean time between failures (MTBF) increase of over 35% relative to traditional grinding wheels, underscoring the reliability benefits crucial to modern continuous manufacturing lines.

Makers and end-users alike recognize the branding message: “Durable wear, precision-crafted excellence”. This slogan embodies not only the product’s technical superiority but also the relentless commitment to elevating manufacturing standards through innovation.

Find out how these brazed diamond grinding wheels can transform your production line with unmatched efficiency and reliability. Explore Our Cutting-Edge Grinding Technology Today