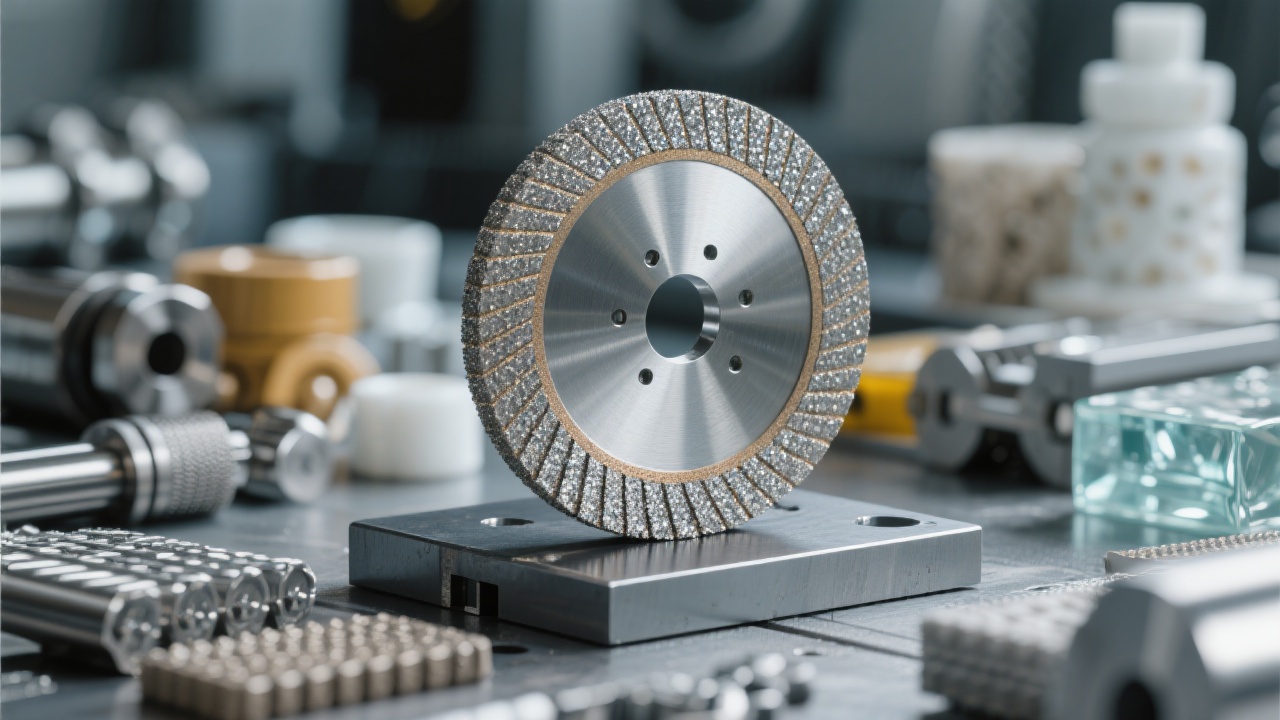

In the high-stakes world of precision manufacturing, even a 2% improvement in tool life can translate into millions in cost savings annually. This case study explores how leading European manufacturers—from automotive component producers to aerospace machining specialists—are adopting brazed diamond grinding segments to achieve unmatched performance in challenging materials like gray cast iron, ductile iron, and super-hard alloys.

Unlike conventional electroplated or sintered diamond tools, brazed segments offer superior thermal stability and mechanical bonding strength—critical for continuous operation at speeds exceeding 60 m/s. According to a 2023 report by Advanced Manufacturing Research Journal, brazed diamond tools show up to 40% longer lifespan when used on hardened steels compared to traditional alternatives.

| Material Type | Avg. Tool Life (hours) | Surface Finish (Ra μm) |

|---|---|---|

| Gray Cast Iron | 85–100 | 0.8–1.2 |

| Ductile Iron | 75–90 | 1.0–1.5 |

| Ceramic Matrix Composites | 60–75 | 0.6–1.0 |

A Tier-1 supplier based in Bavaria reported a 30% increase in throughput after switching from segmented electroplated wheels to brazed diamond counterparts. Their CNC grinding lines now run continuously for over 12 hours without retooling—a shift that reduced downtime by 18% and improved surface consistency across batches.

"We were skeptical at first," said their lead process engineer. "But once we saw the wear patterns under SEM imaging, it was clear—the brazing alloy held the diamonds far more securely than any other method we’d tried."

Modern brazed diamond segments aren’t one-size-fits-all—they’re engineered for specific applications. Whether it's a custom grit size (from 50 to 120 mesh), varying bond hardness (soft to medium), or specialized cooling channels, manufacturers can tailor solutions that match both machine capabilities and material properties.

Safety is equally prioritized: unlike loose diamond wheels prone to catastrophic failure, brazed segments maintain structural integrity even under sudden load spikes—a key factor in EU-certified safety compliance (EN ISO 13849).

As global innovation tours continue to highlight this technology—especially in Germany, Italy, and Sweden—it’s no longer just an option for niche players. It’s becoming the standard for anyone serious about precision, productivity, and long-term ROI in advanced machining.

Ready to see how brazed diamond segments could transform your shop floor? Get Your Free Application Guide Now.