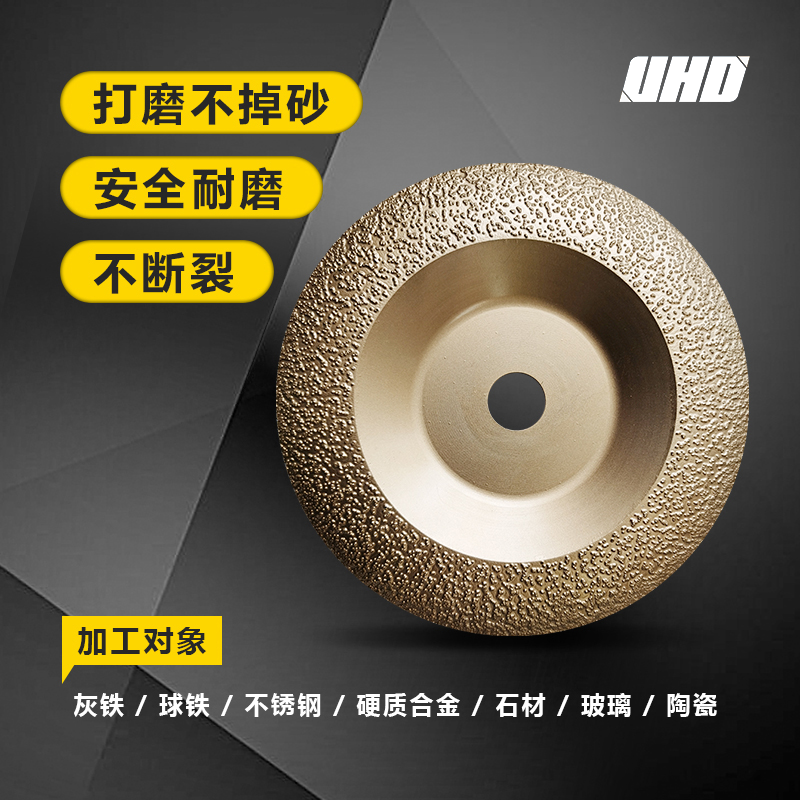

The brazing process is a key factor in the performance of Brazed Diamond Grinding 100. It significantly improves the bonding strength between diamond particles and the substrate. Traditional grinding tools often suffer from diamond particles falling off during the grinding process, which not only shortens the tool life but also affects the grinding quality. In contrast, the advanced brazing technology used in Brazed Diamond Grinding 100 can increase the bonding strength by up to 80%, effectively preventing diamond particles from falling off prematurely. This results in a tool life that is 2 - 3 times longer than conventional grinding tools, truly making “durability a hard truth”.

Brazed Diamond Grinding 100 demonstrates excellent performance across a wide range of materials. For gray iron and ductile iron, it can achieve a surface roughness of Ra 0.8 - 1.6μm, which is much smoother compared to traditional grinding tools. When it comes to stainless steel, its high - temperature resistance and anti - adhesion properties allow for continuous and efficient grinding, reducing the occurrence of grinding burns and cracks. In the case of hard alloys, stones, glass, and ceramics, it shows superior cutting ability, ensuring high - precision processing. The following table shows the performance comparison of Brazed Diamond Grinding 100 on different materials:

| Material | Surface Roughness (Ra) | Grinding Efficiency Improvement |

|---|---|---|

| Gray Iron | 0.8 - 1.6μm | 40% |

| Stainless Steel | 1.0 - 2.0μm | 35% |

| Ceramics | 0.6 - 1.2μm | 50% |

A mechanical processing factory provides a vivid example of the effectiveness of Brazed Diamond Grinding 100. Before using this product, the factory faced low processing efficiency and frequent tool changes. After switching to Brazed Diamond Grinding 100, the data showed significant improvements. The processing efficiency increased by 30%, and the tool - changing frequency decreased by 50%. The specific process involved replacing the original traditional grinding wheels with Brazed Diamond Grinding 100. The operators found that the new tool could maintain a stable cutting state for a longer time, reducing the time spent on tool adjustment and replacement. This not only saved costs but also improved the overall production capacity of the factory.

.png)

When selecting the appropriate Brazed Diamond Grinding 100, different diameters (100mm - 180mm) and aperture/thickness specifications should be considered according to the specific application scenarios. For small - scale precision grinding, such as the internal grinding of small parts, a smaller diameter (100mm - 120mm) tool is more suitable. It can provide higher precision and better control. For large - area grinding, a larger diameter (160mm - 180mm) tool can improve the grinding efficiency. The thickness and aperture also affect the tool's stability and adaptability to different grinding machines. Therefore, users should choose the right specifications based on their actual needs to ensure “every cut is more precise and efficient”.

More and more enterprises are turning to brazed diamond grinding tools to replace traditional grinding wheels. This is mainly due to the increasing demand for high - precision and high - efficiency processing in modern manufacturing. Traditional grinding wheels have limitations in terms of tool life, processing accuracy, and adaptability to difficult - to - machine materials. In contrast, brazed diamond grinding tools, represented by Brazed Diamond Grinding 100, can meet these requirements. The market share of brazed diamond grinding tools is expected to increase by 20% in the next three years, indicating a strong development trend in the industry.

.png)

If you want to experience the high - performance grinding of Brazed Diamond Grinding 100 and improve your production efficiency, click here to learn more and make a purchase!