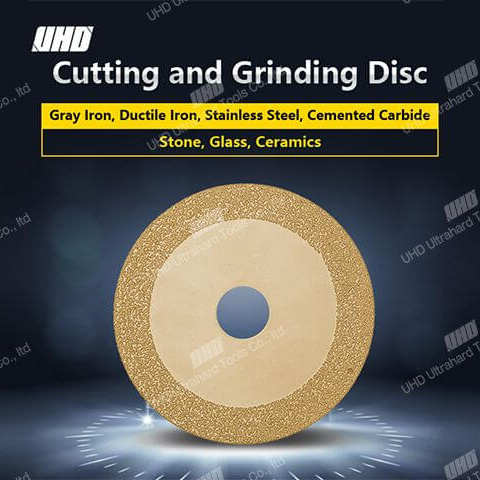

In the demanding world of industrial grinding, maintaining efficiency, durability, and safety remains paramount. The introduction of welded diamond grinding wheels by Youde represents a significant leap forward, redefining the benchmarks for high-performance grinding tools. These grinding wheels combine ultra-hard diamond particles with advanced brazing technology, resulting in an exceptional balance between longevity and precision. The recent global process innovation tour has showcased these products' remarkable capabilities, underscoring their transformative impact across various materials and applications.

At the heart of Youde’s welded diamond grinding wheels lies three core attributes that elevate grinding operations:

“Youde’s innovation in welded diamond bonding sets a new global standard for grinding precision and durability. Their commitment to safety and lasting performance positions them as leaders in industrial abrasives.” — Dr. Karen Mitchell, Materials Science Expert

Unlike traditional adhesives or mechanical fastening methods, Youde’s brazing process forms a metallurgical bond that optimally secures the diamond particles onto the wheel substrate. This results not only in superior adhesion strength but also enhances thermal conductivity, effectively dissipating heat during grinding. This innovation contributes to a significant:

| Performance Metric | Youde Welded Grinding Wheel | Conventional Grinding Wheel |

|---|---|---|

| Tool Life Increase | Up to 60% | Baseline |

| Heat Dissipation Efficiency | Improved by 35% | Standard |

| Particle Shedding Risk | Minimal | Moderate to High |

These improvements translate directly into higher productivity, safer operations, and reduced maintenance intervals. This makes Youde welded diamond grinding wheels particularly suited for industries where uptime and reliability are non-negotiable.

The global innovation tour provided firsthand exposure to end-users from the automotive, aerospace, and heavy machinery sectors. Feedback consistently highlighted the wheels’ “remarkable endurance under continuous operation” and “significant reduction in grinding wheel replacement frequency.” Industry leaders commend this technology for raising the bar in abrasive tool performance.

One aerospace manufacturing manager noted: “Switching to Youde’s welded diamond wheels was a game changer. We experienced a 50% increase in grinding cycles with no compromise on precision, embodying the ‘durable is the rule of thumb’ principle.”

Traditional resin-bonded or mechanically fixed diamond wheels have limitations in wear resistance and bonding strength. By comparison, Youde’s welded diamond grinding wheels deliver a superior lifespan and improved cutting stability, especially in high-stress environments.

Additionally, the wheels’ design complexity—from 100mm to 180mm diameters and flat to contoured surfaces—caters to highly specific grinding tasks, making them versatile alternatives for any challenging application scenario.

Durability is the bottom line. With Youde’s welded diamond grinding wheels, every cut counts, making each cycle not only efficient but also more assured: “Let every cut be confidently secure.”

Empower your production with grinding wheels engineered for longevity and precision. Experience the next generation of welded diamond grinding technology — where durability meets perfected craft.