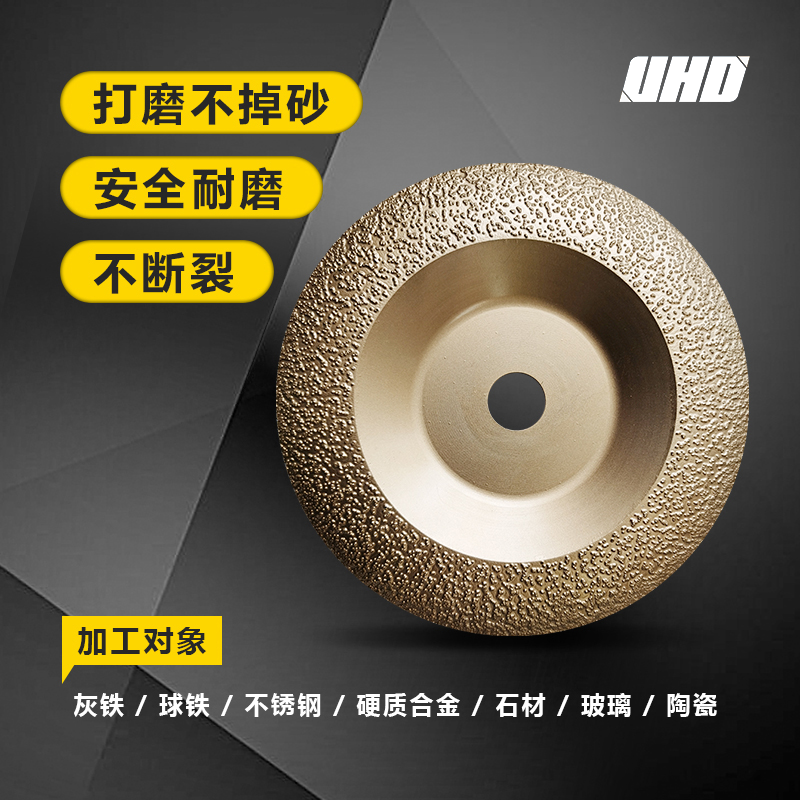

In the field of high - strength material grinding, traditional grinding tools often face challenges such as low efficiency and poor wear - resistance. The development of brazed diamond grinding tools by Henan Youde Superhard Tools Co., Ltd. is a significant innovation. The advanced brazing technology and turning matrix design are the key factors that distinguish this product from others in the market.

The brazing process forms a strong chemical bond between the diamond and the matrix. Compared with traditional mechanical embedding methods, this bond can withstand greater shear forces. Tests show that the bonding strength of brazed diamond grinding tools can reach up to 80 - 90 MPa, which is 2 - 3 times higher than that of traditional grinding tools. The turning matrix design, on the other hand, optimizes the distribution of diamond particles, increasing the contact area between the grinding tool and the workpiece. This design can improve the grinding efficiency by 30% - 40%.

This grinding tool is suitable for a wide range of materials, including gray iron, ductile iron, and stainless steel. In the processing of gray iron, it can reduce the surface roughness by 40% - 50%, achieving a smoother surface finish. For stainless steel, the grinding efficiency is significantly improved, and the processing time can be reduced by about 35%. The following table shows the application advantages in different materials:

| Material | Advantages |

|---|---|

| Gray Iron | Reduced surface roughness, improved finish |

| Ductile Iron | High - efficiency grinding, extended tool life |

| Stainless Steel | Shortened processing time, improved productivity |

To achieve high - efficiency grinding, several key factors need to be considered. First, the selection of the appropriate grinding parameters, such as grinding speed, feed rate, and depth of cut. For example, when grinding gray iron, a grinding speed of 25 - 30 m/s, a feed rate of 0.1 - 0.2 mm/r, and a depth of cut of 0.05 - 0.1 mm can achieve the best results. Second, the correct use of coolant can effectively reduce the temperature during grinding, improving the grinding quality and tool life.

The high - wear resistance of the brazed diamond grinding tool is mainly due to the high - quality diamond particles and the excellent brazing process. The diamond particles used have a high hardness and thermal stability, which can withstand high - temperature and high - pressure grinding environments. The brazing process ensures that the diamond particles are firmly fixed on the matrix, reducing the shedding of diamond particles during grinding. Tests show that the service life of this grinding tool can be 5 - 8 times longer than that of traditional grinding tools.

A manufacturing company in the automotive industry used the brazed diamond grinding tool to process engine cylinder blocks made of gray iron. After using this tool, the grinding efficiency increased by 40%, and the tool life was extended by 6 times. This not only reduced the tool replacement frequency but also improved the overall production efficiency, resulting in a significant cost reduction.

.png)

The brazed diamond grinding tool has obvious market competitive advantages, such as high efficiency, long service life, and wide application range. Henan Youde Superhard Tools Co., Ltd. is committed to providing high - quality products and excellent after - sales service. The company's professional technical team can provide users with customized grinding solutions and on - site technical support.

Are you looking for a high - performance grinding solution? Don't miss out on our brazed diamond grinding tools! Click here to learn more.