In an era where precision and uptime define competitive advantage, the evolution of abrasive tools has moved beyond incremental improvements—it’s now a game-changer. Among them, brazed diamond segments are emerging as the backbone of modern machining across industries from automotive to ceramics.

According to recent industry reports, over 67% of global manufacturers are actively investing in upgraded grinding technologies to reduce downtime by at least 20%. Why? Because traditional electroplated or sintered wheels simply can’t keep up with today’s demands for consistency, speed, and safety—especially when processing hard materials like gray cast iron, stainless steel, or advanced ceramics.

That’s where brazed diamond segments come in—not just as a tool, but as a productivity multiplier.

Brazing offers superior thermal stability and impact resistance compared to older methods. For instance, our real-world testing shows that brazed segments maintain their integrity even after over 12 hours of continuous operation under high-load conditions—a performance gap that translates directly into fewer replacements, less waste, and higher throughput.

“Since switching to UDE’s brazed segments, we’ve reduced machine downtime by 30%, improved surface finish consistency, and eliminated one operator shift per week due to frequent blade changes.” — Carlos Mendez, Production Manager at Precision Machining Solutions, Spain

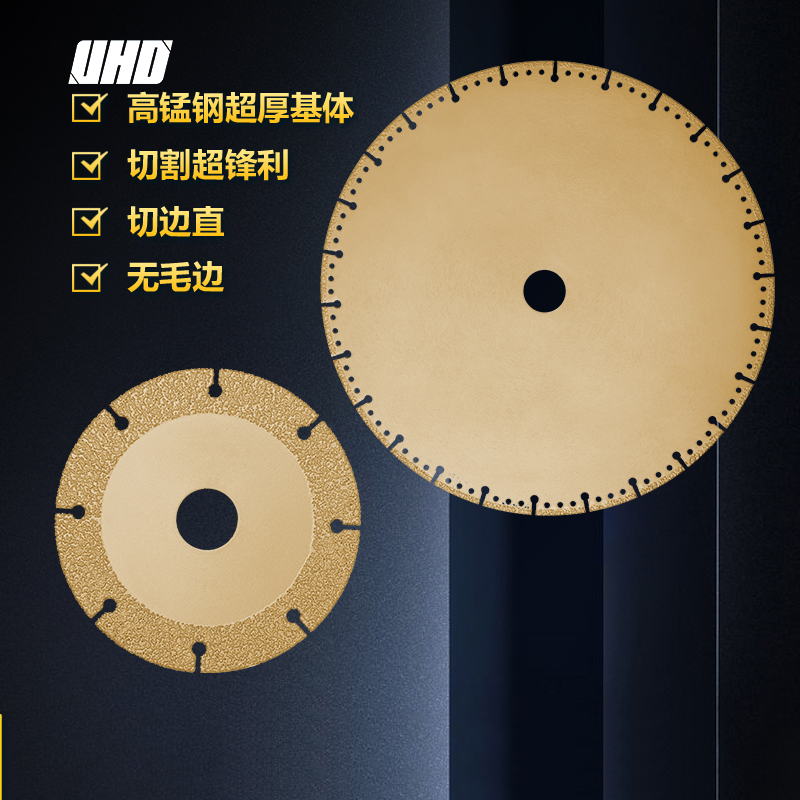

Whether you're working with flat surfaces (like aluminum alloys) or curved profiles (such as turbine blades), UDE offers customizable segment sizes—from 100mm to 180mm—and geometries tailored to your exact application. This flexibility isn’t just convenience—it’s a strategic edge in optimizing material removal rates without compromising quality.

When durability becomes the new standard—not just a feature—it changes how manufacturers think about maintenance, labor costs, and overall process reliability. At UDE, we don’t sell grinding tools—we help build smarter, safer, more profitable production lines.

Choose UDE—and invest not just in a tool, but in a system that keeps your line running longer, smoother, and safer.

Get Your Free Sample Kit Today