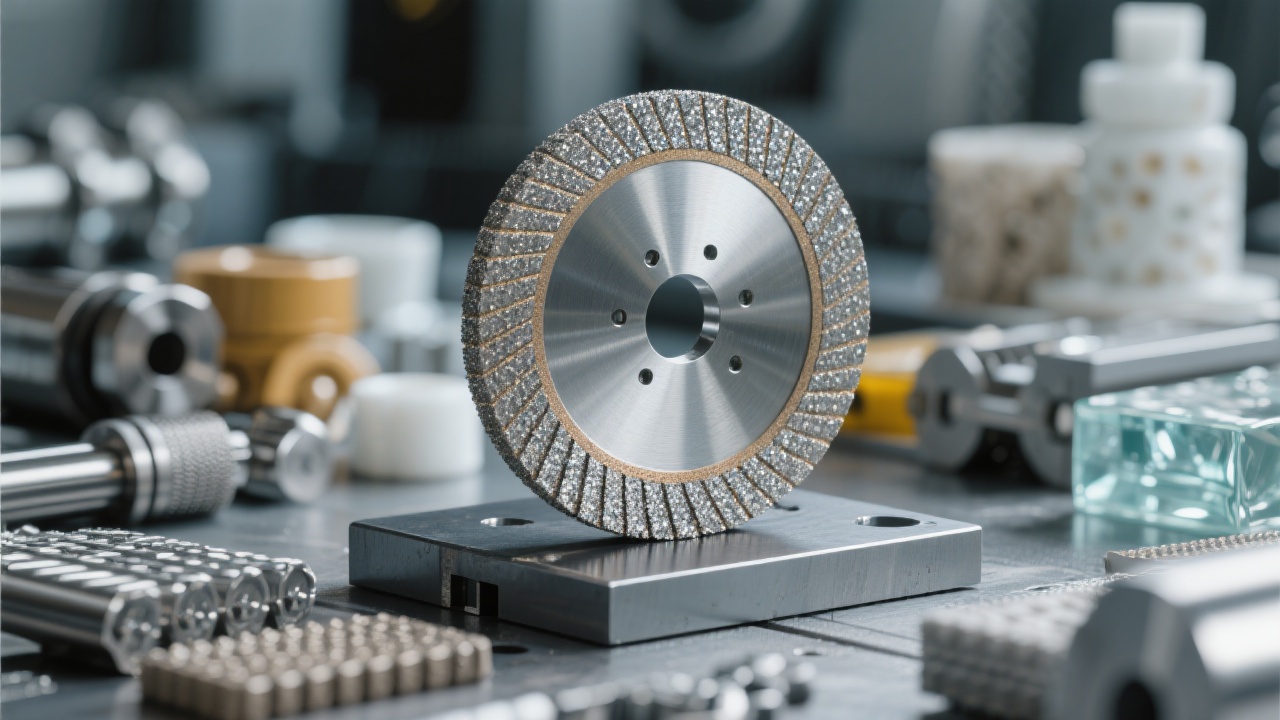

Industrial manufacturing is constantly seeking innovative solutions to enhance efficiency and reduce costs. Brazed diamond grinding discs have emerged as a revolutionary tool in this pursuit. Understanding the basic principles of brazed diamond grinding discs is crucial to appreciating their advantages over traditional welding methods.

The brazing process used in these grinding discs involves a unique bonding technique that securely attaches super - hard diamond particles to the base. Compared with traditional welding, this method provides a stronger bond, which allows the diamond particles to withstand higher pressures and temperatures during the grinding process. For example, traditional welding may have a bond strength that can withstand up to 200 MPa, while the brazing process in these discs can reach bond strengths of over 300 MPa, resulting in a more stable and durable grinding tool.

One of the significant features of brazed diamond grinding discs is their excellent performance on various materials. Let's take a look at how they perform on different materials:

| Material | Traditional Grinding Tool Efficiency | Brazed Diamond Grinding Disc Efficiency | Efficiency Improvement |

|---|---|---|---|

| Cast Iron | Grinding rate of 50 cm³/min | Grinding rate of 80 cm³/min | 60% |

| Stainless Steel | Grinding rate of 30 cm³/min | Grinding rate of 55 cm³/min | 83.3% |

| Stone | Grinding rate of 40 cm³/min | Grinding rate of 70 cm³/min | 75% |

These data clearly show that brazed diamond grinding discs can significantly improve the grinding efficiency on different materials.

In real - world industrial applications, the extended service life of brazed diamond grinding discs brings substantial cost savings. A case study in a metal processing factory showed that when using traditional grinding tools, the average service life was about 200 hours, and the tool needed to be replaced every 20 hours, resulting in high replacement costs and downtime. In contrast, the brazed diamond grinding discs had a service life of over 800 hours, with a replacement interval of over 80 hours. This means that the replacement frequency was reduced by 75%, and the overall cost of grinding tools was reduced by about 60%.

Besides efficiency and cost - savings, the design details of brazed diamond grinding discs also focus on safety. The anti - stamping structure ensures that the disc can withstand high - impact forces during operation, reducing the risk of disc breakage. Additionally, the safety protection design provides a shield for both operators and equipment. An expert in the field once said, "The safety features of these grinding discs are a game - changer in the industrial grinding industry, as they not only protect the workers but also safeguard the expensive equipment from potential damage."

Brazed diamond grinding discs are driving the manufacturing industry towards higher precision and lower maintenance requirements. With their high efficiency, long service life, and safety features, they are becoming an indispensable tool in modern manufacturing. As technology continues to evolve, we can expect even more improvements in the performance of these grinding discs.

Durability is the hard truth, and our brazed diamond grinding discs are crafted with precision. Seize the opportunity to enhance your industrial processing efficiency with our high - quality products. Click here to learn more and start your journey towards cost - effective and efficient grinding!