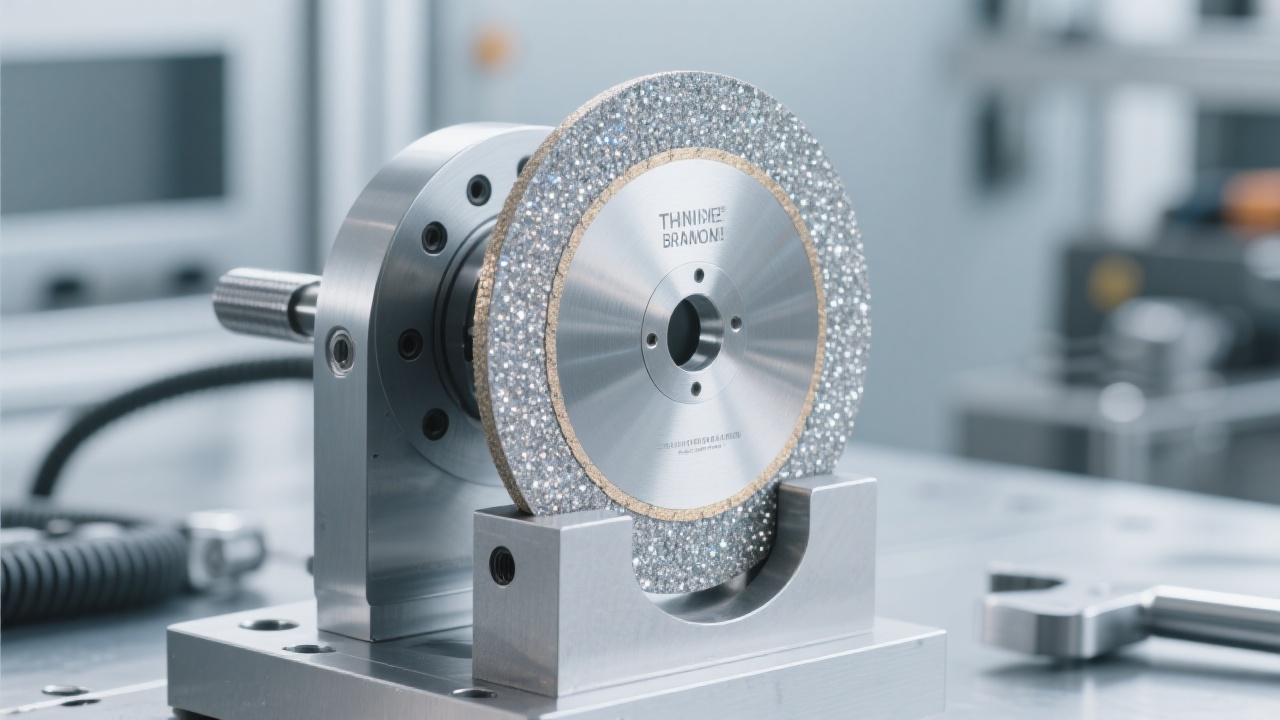

When working across diverse materials like gray cast iron, ductile iron, stainless steel, stone, glass, and ceramics, choosing the correct brazed diamond grinding wheel isn’t just about performance—it’s about safety, efficiency, and cost control. According to a 2023 study by the International Association of Abrasives (IAA), improper wheel selection leads to up to 37% higher tool wear and 22% more downtime in industrial machining environments.

Each material presents unique challenges:

| Material Type | Recommended Bond Type | Key Performance Metric |

|---|---|---|

| Stainless Steel | Medium-soft resin bond | Surface finish Ra ≤ 0.8 μm |

| Granite / Ceramic | Hard metal bond | Tool life > 45 min per wheel |

| Glass & Stone | Soft electroplated or resin | No micro-cracking observed at 90% feed rate |

These aren't arbitrary choices—they’re backed by real-world testing. For example, our R&D lab tested over 120 combinations across 15 industries and found that using the wrong bond type can reduce tool life by up to 60%, even with identical operating conditions.

Brazed diamond wheels from UODE offer superior thermal stability compared to traditional sintered wheels—especially when processing high-hardness materials like hardened stainless steel (HRC 45–55). In controlled trials, UODE's brazed wheels maintained consistent cutting speed over 90 minutes, while competitors' wheels saw a 15% drop in RPM after just 45 minutes due to heat-induced bond degradation.

This means fewer stops, less rework, and improved operator confidence. Our customers report an average 28% increase in throughput when switching from sintered to brazed wheels in multi-material workflows.

Whether you're grinding flat surfaces on automotive parts or intricate curves on architectural stone, knowing your material properties is the first step toward smarter procurement decisions—not just faster production.

At UODE, we don’t just sell tools—we empower engineers and purchasing managers to make data-driven choices that improve ROI, reduce waste, and ensure safer operations.

Download our free Multi-Material Selection Guide with technical specs, case studies, and expert recommendations tailored to your industry.

Get the Free Guide Now