When it comes to high-precision machining, selecting a brazed diamond grinding wheel that delivers durability, efficiency, and safety is critical to your operations. Whether you're a mechanical engineer or a tooling procurement specialist, understanding the intricacies behind choosing the optimal grinding wheel can elevate your production quality and protect your equipment investment.

The current manufacturing landscape demands grinding tools that excel beyond traditional expectations. Your grinding wheel must provide:

Brazed diamond grinding wheels have emerged as technological frontrunners by addressing these precise needs, significantly outperforming electroplated or sintered wheels in critical performance parameters.

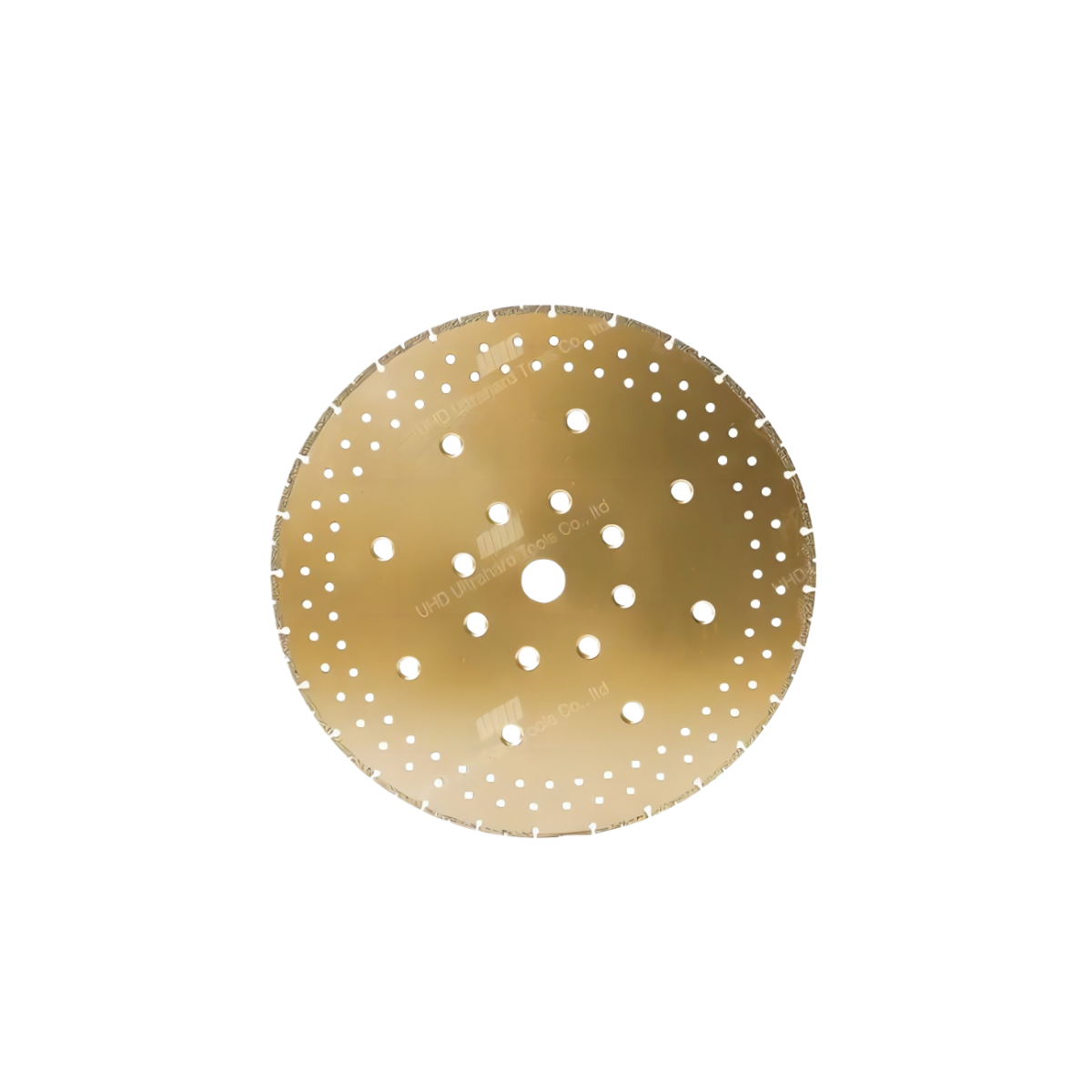

The innovative brazing process bonds diamond particles securely to the steel core using a copper-based alloy, resulting in a wheel that combines:

| Feature | Benefit |

|---|---|

| Higher diamond retention | Improved durability and longer wheel life |

| Enhanced heat dissipation | Reduced thermal damage to workpieces and tool |

| Superior bond strength | Reliable performance even in high-impact and heavy-duty contexts |

Matching your brazed diamond grinding wheel to the specific material you process is vital. Consider the following typical applications and compatible wheel types:

| Material | Recommended Wheel Type | Key Considerations |

|---|---|---|

| Gray Cast Iron | Standard brazed diamond wheel | Focus on smooth cut quality and heat resistance |

| Ductile (Nodular) Cast Iron | High-strength brazed wheel with enhanced diamond concentration | Optimize bond strength to prevent premature diamond loss |

| Stainless Steel | Premium brazed wheel with fine grit and thermal stability | Prioritize heat dissipation and surface finish |

| Stone & Ceramic | Superabrasive brazed wheels with curved or profile designs | Ensure shape retention and crack resistance |

The shape and diameter of the grinding wheel affect its grinding efficiency and compatibility with your machinery:

To maximize your return on investment, factor in the following when selecting your brazed diamond grinding wheel:

| Consideration | Guideline |

|---|---|

| Machinery type | Match wheel diameter and bore size precisely to your machine’s specifications to maintain balance and rotational speed ratings (RPM). |

| Grinding precision | Choose finer grits and well-controlled diamond particle distribution for tight tolerance tasks. |

| Batch volume | High-volume production demands wheels with superior wear life and easy maintenance; low-volume or specialized jobs may benefit from custom shapes. |

Paying attention to detail such as hand measurement precision and verifying the impact resistance rating of wheels can drastically reduce downtime and unexpected failure. When selecting a brand, look for those that emphasize these quality facets—because in grinding, durability is the bottom line.

Implementing a data-driven, scientifically guided approach to grinder wheel selection will:

Trust the principle: “lasting durability, precision crafted” isn’t just a tagline—it’s the pathway to your leaner, more efficient manufacturing process.

Discover Your Perfect Brazed Diamond Grinding Wheel Today — Elevate Performance & Safety