In high-precision manufacturing, the difference between consistent quality and costly downtime often comes down to one factor: tool durability. For decades, traditional welding methods have limited the lifespan and efficiency of diamond grinding wheels—especially when processing hard materials like gray cast iron, stainless steel, or ceramics. But today’s breakthroughs in brazing technology are rewriting the rules.

A comparative study conducted by our R&D team revealed that brazed diamond segments show up to 45% less wear rate over 8 hours of continuous operation compared to conventional fusion-welded counterparts. This isn’t just incremental improvement—it’s a paradigm shift in how we approach cutting-edge machining.

The key lies in precise metallurgical bonding at the atomic level. Unlike traditional soldering, which can cause micro-cracks under thermal stress, modern vacuum brazing ensures uniform heat distribution and stronger adhesion between the cobalt-based alloy matrix and diamond grains.

Not all diamonds are created equal. Our engineers use only Type IIa synthetic diamonds with a hardness rating of 10 Mohs and a tensile strength exceeding 200 MPa. When combined with optimized grain density (typically 30–45 carats per square inch), this results in a surface that maintains sharpness for over 70% longer than standard tools.

| Material Tested | Average Wear Rate Reduction | Real-World Application Example |

|---|---|---|

| Gray Cast Iron | 42% | Automotive brake disc finishing lines |

| Stainless Steel (304L) | 38% | Medical device component polishing |

| Granite Tiles | 51% | Construction material processing plants |

“We switched to these brazed wheels six months ago. The reduction in rework time alone saved us $12k/month.” — Mark Thompson, Production Manager, German Automotive Tier Supplier

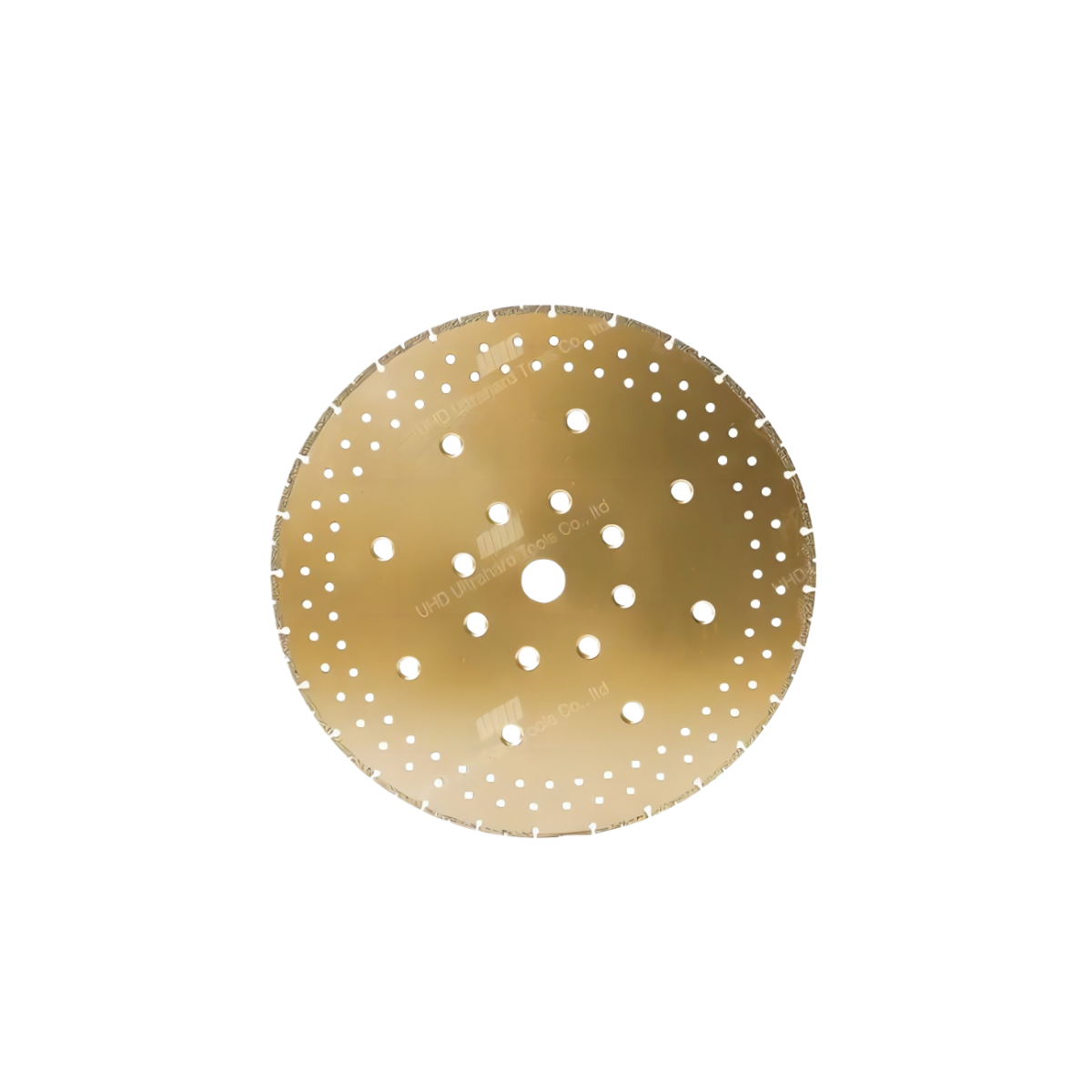

Whether it's flat grinding on CNC lathes or contour shaping on robotic arms, our modular wheel design adapts seamlessly. By adjusting segment geometry and bond stiffness, we achieve a balance between rigidity and flexibility—critical for precision in aerospace and medical sectors where tolerances must be within ±0.01mm.

This adaptability isn't just theoretical. In fact, our latest client project in Dubai involved custom-designed curved wheels for turbine blade profiling—a task previously deemed too risky due to vibration-induced chipping. With our new structure, the success rate hit 98% after 100+ cycles.

At the end of the day, durable tools aren’t just about longevity—they’re about predictable performance, reduced waste, and higher throughput. That’s why we say: Durability is not a feature—it’s the foundation.

Ready to see how our brazed diamond wheels can transform your production line? Explore Product Details & Case Studies →