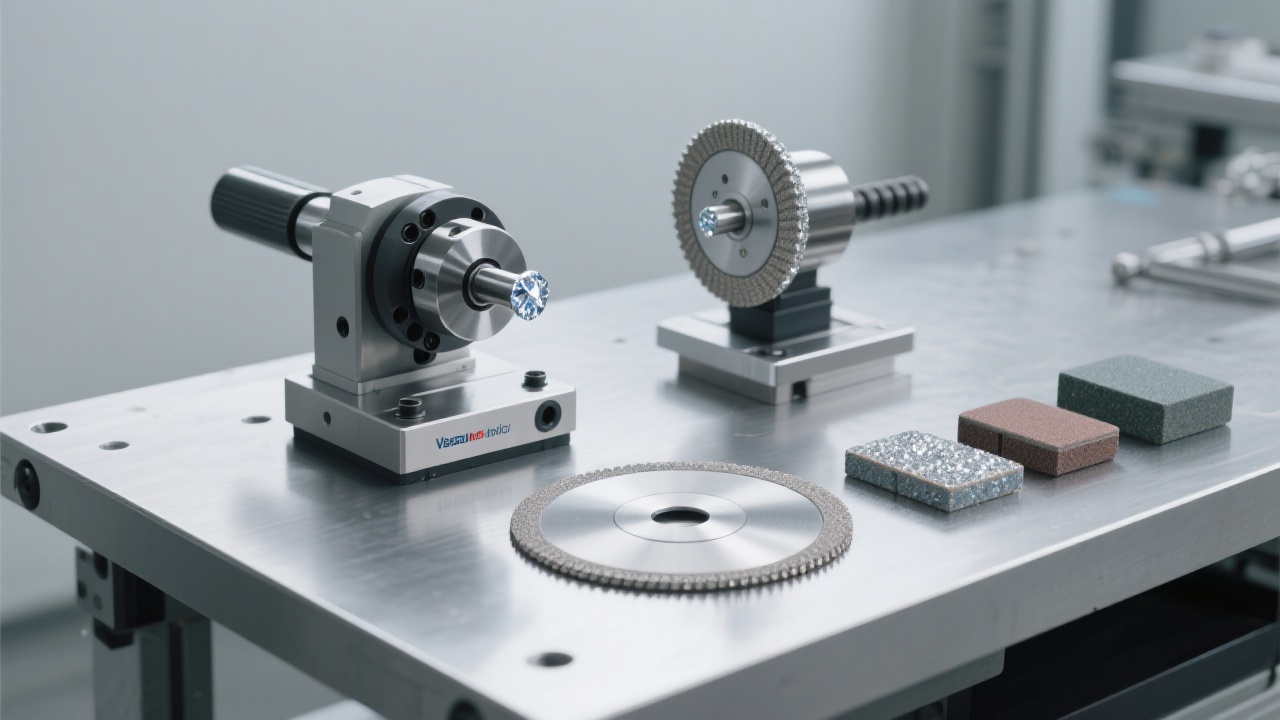

The brazed diamond grinding disc is a product designed for high - standard processing fields. In modern industrial processing, there is an increasing demand for high - precision and high - efficiency grinding tools. This grinding disc is suitable for a variety of hard alloys and non - metallic materials, such as gray iron, ductile iron, and other hard materials. For example, in the automotive manufacturing industry, when processing engine parts made of gray iron, the brazed diamond grinding disc can ensure high - quality surface finishing.

The product features innovative brazing technology and the use of super - hard diamond particles. The brazing technology ensures a strong bond between the diamond particles and the substrate. The diamond particles have a hardness of up to 10 on the Mohs scale, which is much higher than traditional abrasive materials. This combination allows the grinding disc to maintain its sharpness during long - term use. Data shows that compared with traditional grinding discs, the brazed diamond grinding disc can increase the grinding efficiency by up to 30%.

The brazed diamond grinding disc has excellent wear - resistance. Its innovative design and high - quality materials can reduce the wear rate by 50% compared with ordinary grinding discs. In terms of fracture resistance, the special brazing technology and the reasonable distribution of diamond particles can effectively prevent the grinding disc from breaking during high - speed rotation. In terms of safety, the grinding disc has a balanced structure, which can reduce vibration during operation and protect the safety of operators. According to statistics, the accident rate caused by grinding disc failure has been reduced by 40% after using this product.

The brazed diamond grinding disc comes in a variety of specifications, with diameters ranging from 100mm to 500mm and thicknesses from 5mm to 20mm. This wide range of specifications can meet different processing requirements. For example, a small - diameter grinding disc is suitable for fine - processing of small parts, while a large - diameter grinding disc can be used for large - area grinding operations.

The upcoming Global Process Innovation Tour is a great opportunity to showcase the brand's strength. At the exhibition, visitors can have an in - depth understanding of the brazed diamond grinding disc through product displays, on - site demonstrations, and interactive experiences. This kind of exhibition not only shows the brand's professional strength and innovative spirit but also provides a platform for users to communicate and learn.

By using the brazed diamond grinding disc, users can significantly improve processing efficiency. The high - efficiency grinding performance can reduce the processing time, and the long - service life can reduce the frequency of replacing grinding discs. At the same time, the safety features of the product can protect the safety of operators and reduce the risk of accidents.

The brazed diamond grinding disc is of great significance for high - standard processing in the industry. It can help enterprises improve product quality, reduce production costs, and enhance market competitiveness. In the future, with the continuous development of technology, the brazed diamond grinding disc is expected to be more intelligent and environmentally friendly, meeting the ever - increasing requirements of the industrial market.

Choose the Youde brand's brazed diamond grinding disc for the best process experience!