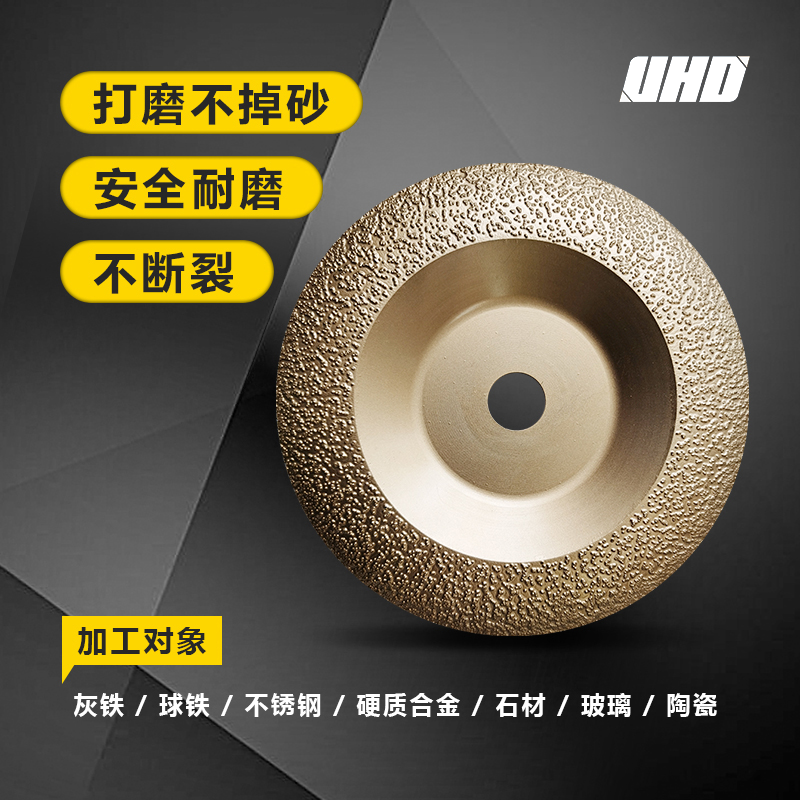

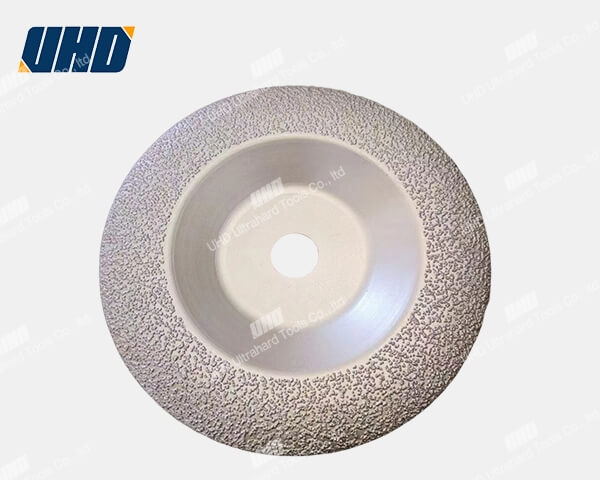

In high-demand industrial environments—from automotive components to precision molds—manufacturers are turning to brazed diamond grinding tools like the Grinding Wheel 100 to solve persistent challenges in wear resistance, thermal stability, and cutting efficiency. Unlike conventional abrasives that degrade quickly under stress, this tool delivers consistent performance across demanding materials such as gray cast iron, stainless steel, and ceramics.

What sets it apart? The advanced brazing process ensures a strong metallurgical bond between the diamond layer and the substrate, resulting in a structure that resists chipping, delamination, and heat-induced deformation—even at speeds exceeding 60 m/s.

| Feature | Traditional Bonded Wheels | Brazed Diamond Wheel 100 |

|---|---|---|

| Average Lifespan (hours) | 15–25 | 60–90 |

| Thermal Stability (°C) | ≤400 | ≥650 |

| Cutting Force Reduction (%) | N/A | Up to 35% |

These improvements translate directly into lower downtime, reduced labor costs, and better surface finish quality—especially critical in industries where tolerances must be maintained within ±0.01 mm.

At a Tier-1 automotive supplier in Germany, the adoption of these wheels led to a 40% reduction in tool change frequency during crankshaft grinding operations—a key factor in maintaining throughput without compromising accuracy. Similarly, a Chinese mold-making facility reported a 27% increase in productivity after switching from resin-bonded wheels to brazed diamond solutions.

“We’ve tested dozens of brands over five years. Only one consistently met our standards for durability and precision—this is why we now use only brazed diamond wheels.” — Production Manager, Automotive Components Plant, Stuttgart

With customizable diameters (from 100mm to 400mm), hole sizes (ISO-standard or custom), and edge thickness options (3mm–12mm), the Grinding Wheel 100 adapts seamlessly to CNC grinders, surface grinders, and specialized equipment used globally.

Backed by over 15 years of R&D at Henan Yude Superhard Tools Co., Ltd., each unit undergoes rigorous QC checks—including microstructure analysis, load testing, and real-world validation—to ensure reliability across diverse global markets.

For manufacturers who prioritize long-term ROI over short-term savings, durable tools aren’t just an option—they’re essential. At Yude, we believe: “Durability is not a feature—it’s the foundation of every successful production cycle.”

Explore Product Specifications & Technical Support